Call us 800-410-6580

Maintenance for your TrailerSaver 5th-Wheel Air-Ride Hitch

As the owner of any product that must hold up to the rigors of a heavy trailer and rough roads, maintenance is critical for the longevity and trouble-free use of your TrailerSaver air-ride hitch. The following checklist is a handy guide to make sure you address everything that is required to keep your hitch operating as it was intended. We recommend completing this maintenance every 1,000 miles or once a year, whichever comes first.

Step 1: Grease Fitting Lubrication

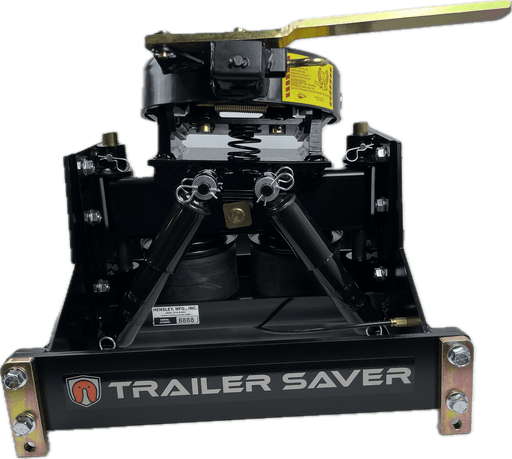

Lubrication for the BD series TrailerSaver hitch:

For the BD hitches, locate the two half-moon shaped cutouts at the end of your beam assembly. Inside those are the grease fittings. Insert your grease gun onto the fitting until you feel a click and pump in just enough grease until you see it starting to ooze out just a little bit above the bushing.

It is recommended to grease this vertical shaft at least every 1,000 miles, but you cannot over grease these, so doing it more often will only help with reducing wear in the bushings.

Note: The grease fittings for the TS3/TSLB models are in different locations than the BD series hitches.

Lubrication for the TS and TSLB TrailerSaver Hitch

For the TS3 and TSLB models, locate the two grease fittings on the top of the swing arm, and pump in just enough grease into both until you see a little grease squeeze out like you see here.

Step 2: Grease Main Pivot Bolt

For both the BD series and TS series hitches, it is also recommended to remove and grease the main pivot bolt at least once a season. Re-install the pivot bolt and snug the large lock nut until the head does move side to side freely but with a little resistance.

Step 3: Spray Grease Pivot Pins

On all TrailerSaver models, be sure to use a quality spray lubricant like white lithium spray grease to lubricate the two pivot pins on both sides of the coupler. Spray through the two access holes above both pins for lubrication to run down and coat each pin. For the grease gun, we recommend using a high-grade grease that is rated NLGI #2 or #3.

Step 4: Check Bolt Torque

Check all structural bolts and make sure they are torqued to 125 feet pounds.

Featured Products

Ultimate Hensley Arrow® Anti-Sway Trailer Hitch - Rated For 3,000 - 16,000lbs

Safety and Confidence when you travelWhen your family, truck, and trailer are on the line, Hensley is a name people have known and trusted for 30 ...

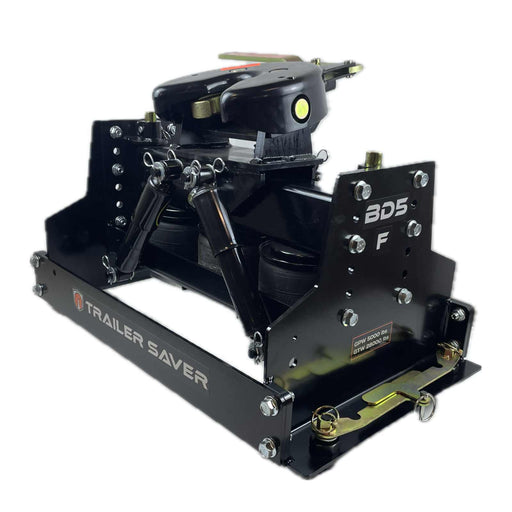

View full detailsTrailerSaver BD5-F Air Ride 5th-wheel Hitch-Ford OEM

The BD5-F Air-Ride 5th-wheel hitch fitch factory installed Ford OEM 5th wheel prep system. Designed to complement an air ride pin box, it has 28,00...

View full detailsTrailerSaver BD3 Air-Ride 5th-Wheel Hitch For Rails

The BD3 Air-Ride hitch is for weekenders and anyone who prefers to keep the hitch out of their truck when not towing. The BD3 breaks down into two ...

View full detailsTrailerSaver TSLB Air-Ride 5th-Wheel Hitch

The TSLB 5th-wheel air-ride hitch is for medium to heavy-duty truck owners. Based on the same design as the TS3, it comes with a standard bolt-down...

View full detailsTrailerSaver TS3 Air-Ride 5th-Wheel Hitch

The TS3 Air-Ride fifth-wheel hitch set the standard for 5th-wheel hitches when it was introduced over 10 years ago. And it still sets the standard....

View full details